Industrial Engineering Consulting Focuses on People… and the value-added activities of direct labor, indirect labor and equipment utilization.

- Plant, Office and Warehouse Studies

- Labor Productivity (Fixed-Interval Sampling)

- Equipment Changeover

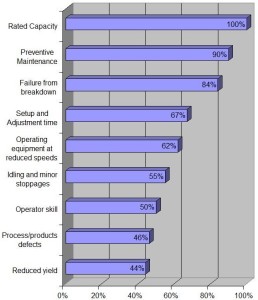

- Overall Equipment Effectiveness (OEE)

- Operator or Equipment Delay

- Work Standards Development

- Time Studies (Stop Watch & Predetermined Work Measurement)

- “Best Practice” Labor Methods Design

- Operator Instruction Sheets Design

- Department, Assembly Line and Workcell Labor Balancing

Typical Industrial Engineering Benefits:

- An enhanced understanding of how your operations are really working from an outside, objective viewpoint.

- Staffing levels that are appropriate to your needs.

- Standardization on “Best Practice” labor methods.

- Significant improvements in labor productivity, plant capacity and quality.