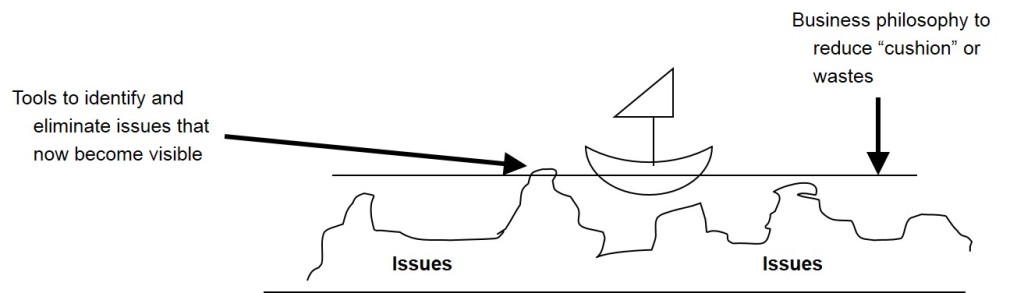

Implement improvements… based on the lean philosophy of Toyota Production Systems.

Epicenter employees have been successfully applying the Lean philosophies and tools for the past twenty years. We can provide as-needed support to your internal Lean efforts through targeted Kaizen events, training and engineering support.

Typical Activities

- Facilitation and Technical Support of a three- or four- day Kaizen team event:

- Value-Stream Mapping, Change-over Reduction (SMED), 5S, Work Standardization, and Lean Layout Development

- General Training Events

- Lean 101 for Executives and Lean 101 Simulation (14 people)

- Development of Executive Systems (Steering Committee, Reporting Structures, etc.)

- Kanban (material control) Systems Design / Implementation

- Manufacturing Workcell Design/Implementation

Typical Benefits

- Reduced Order Lead Time (Significant)

- Reduced Inventory Level / Investment (Significant)

- Improved Production Efficiencies

- Improved System Capacity

- Improved Quality